GreenLight Software Services

Streamlining deployments and maintaining smart building performance

For over a decade, IDS has provided clients with exceptional, reliable and cost-effective IoT deployment services that support their smart building system integrations. And, as a tech-enabled company, we are unique in our ability to develop custom software solutions that can streamline the process and improve the speed, quality and cost of IoT deployments at scale. We also leverage our technical expertise and deep deployment experience to create novel software solutions that can help facility owners monitor the ongoing health of their smart building systems and proactively alert facility operators to potential device issues that can impact overall system performance.

GreenLight Software Services

GreenLight Software Services

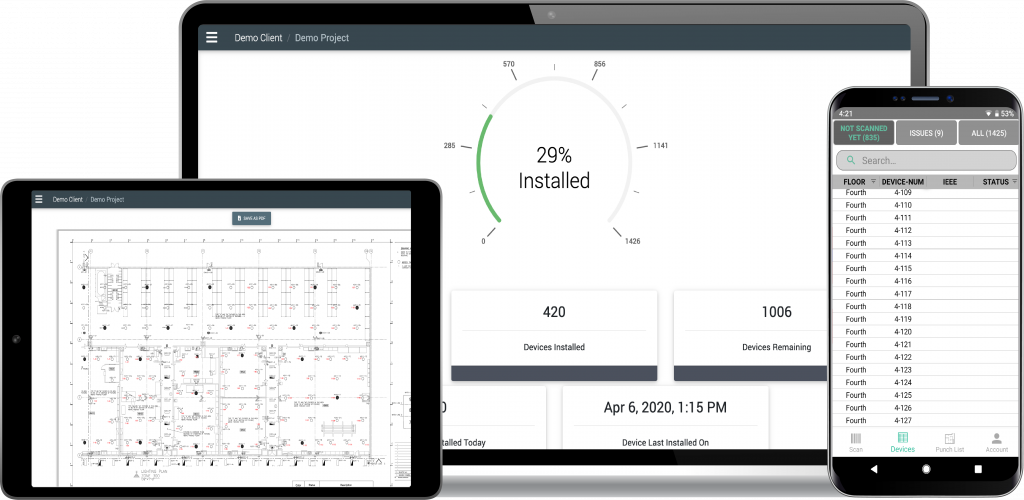

IDS uses GreenLight cloud-based software, mobile apps and smart monitoring technology as part of our overall IoT deployment process to deliver accurate, efficient and cost-effective smart building solutions at scale, and to provide smart automated monitoring that ensures ongoing building system health and performance.

We are delighted to offer direct licensing of our suite of GreenLight software service products to third-party installers, device manufacturers, system integrators, property managers, and Fortune 500 companies. This allows them to seamlessly incorporate our patented technology into their deployment process to simplify and optimize their smart building system installs.

GreenLight Software Services

GreenLight Software Services

IDS uses GreenLight cloud-based software, mobile apps and smart monitoring technology as part of our overall IoT deployment process to deliver accurate, efficient and cost-effective smart building solutions at scale, and to provide smart automated monitoring that ensures ongoing building system health and performance.

We are delighted to offer direct licensing of our suite of GreenLight software service products to third-party installers, device manufacturers, system integrators, property managers, and Fortune 500 companies. This allows them to seamlessly incorporate our patented technology into their deployment process to simplify and optimize their smart building system installs.

GreenLight Software-Enabled Deployment Process

IoT device deployment has historically been a complicated, manual and time-consuming process. At IDS, we’ve designed an advanced, software-based, IoT device deployment solution that makes it easy and cost-effective to deploy enterprise-level smart technology at scale. Our GreenLight software-enabled deployment process features a combination of agile, cloud-based software, mobile applications and innovative services.

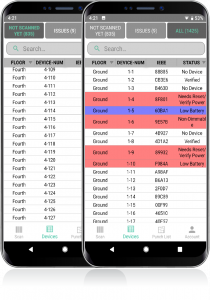

GreenLight Scanner 2.0

The GreenLight scanner mobile app is a multi-purpose tool that integrates into any API, network, or protocol and reduces IoT device deployment time by half. The app functions as a digital scanner to accurately capture and upload essential IoT device details that can automatically build digital asbuilt documents, create real-time punch lists and enable remote commissioning to further enhance the deployment process. Our mobile solution is agile, scalable and easy to use. Plus, it integrates tightly with the GreenLight provisioning platform to deliver the best remote device deployment solution available in the market.

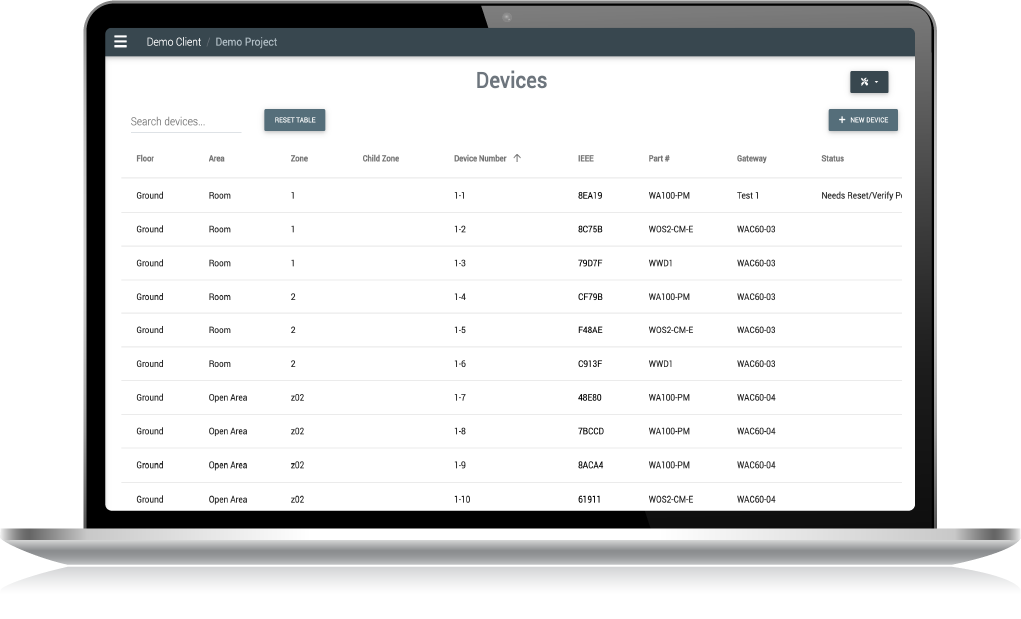

GreenLight Provisioning Platform

Our patented GreenLight provisioning platform is a cloud-based IoT technology platform that offers clients a dynamic and flexible IoT device deployment solution that is exceptionally scalable. Businesses can deploy their enterprise IoT solutions with confidence knowing that the GreenLight software platform supports any IoT device, is operable on any network and adapts to any workflow. Our highly adaptable software platform relays real-time insights and is customizable to a variety of smart building applications.

GreenLight Smart Autonomous Monitoring

The GreenLight smart autonomous monitoring software is our newest service offering that helps businesses maintain their smart building performance over time. It provides autonomous monitoring of IoT devices and systems to enable real-time, health status updates of smart building operations, then proactively alerts building owners or facility operators to potential device issues that may impact overall system performance and require onsite maintenance support.

GreenLight Software Services

GreenLight Software ServicesStreamlining deployments and maintaining smart building performance

GreenLight Software Services

GreenLight Software Services

Streamlining deployments and maintaining smart building performance